Corrugated pipe

Corrugated pipe

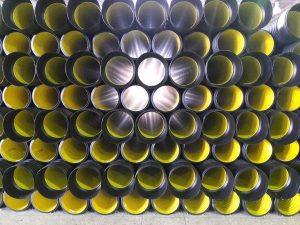

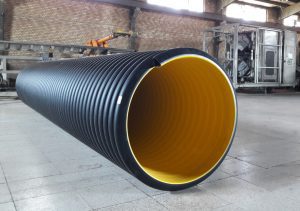

Corrugated pipe or double-walled polyethylene pipe is one of the most widely used types of pipes. In the precise definition of corrugated pipe, it should be said that HDPE or high density polyethylene pipes with a nozzle shape and yellow inner surface are said to be polished due to their advantages and excellent characteristics over other pipes. Different applications are given priority.

Some corrugated pipe companies produce them with fiber coatings, called PVC corrugated pipes. However, the uncoated type has more usable applications. In general, the applications intended for this type of pipes include from water and sewage transfer to protection of valves, which are all due to their high durability, excellent price and low weight.

The structure of these pipes is known by the appearance of grooves or congresses of the outer surface, which, of course, is similar to some other pipes such as spiral or cortisone. In general, the reason for grooving and concreting the outer surface of corrugated pipes is that due to use inside the ground, due to pressure from the surroundings and high forces such as soil and the passage of heavy machinery, it does not crack or break.

The inner wall of the corrugated pipe is smoothed and polished so that in cases where kilometers of piping are required, the liquids and fluids inside it do not drop in pressure and sediment does not form, and when acidic liquids, alkalis and industrial effluents are transferred, the friction and reaction time Minimize the pipe.

What factors determine the lifespan and durability of these pipes?

Carogit pipes will naturally have a high durability and durability when they are made of high quality raw materials, but the thing that plays a role in their longevity and durability after the company that produces Carogit is the conditions and the way of installation and placement.

Due to the fact that corrugated pipes are buried in the ground and a lot of pressure is applied from different directions and upwards, their external grooved state causes this pressure to spread and greatly increase their pressure tolerance, but this state will occur under certain conditions. The soil around the corrugated pipe has no stones, gravel or sharp objects, and therefore thoroughly inspected

Otherwise they will be damaged quickly.

The next case is to check the depth of the excavated soil, proper piping and the use of durable connections that determine the durability and durability of Carogit pipe after installation, because repairs in the ground are very time consuming and costly to For this reason, they must be completely professionally placed, and in these circumstances, they can be expected to work without problems for 50 to 100 years.

Characteristics of corrugated pipe

Carogit pipes in general have features that make their use more cost-effective and convenient than other pipes in every way. In this section, we will mention some of the most important ones, and in the following sections, we will discuss the specific features of Carogit pipes. the payment:

-

The very high resistance of this type of pipe against acidic and alkaline materials, which is called corrosion resistance, has made it suitable for transferring strong acids and bases.

-

Their very high durability and longevity, which we explained the factors that affect it, makes companies feel comfortable for at least 50 years and even up to 100 years.

-

The inner wall of this type of pipe is completely smooth and without protrusions and roughness, and this feature has caused the flow of liquids not to face pressure drop even at very long distances, and on the other hand, with decreasing coefficient of friction, sediment does not form in the pipes. .

-

The flexibility of the corrugated pipe is very high and this factor has caused it not to be damaged except by external pressure from sharp and pebble objects, etc.

-

They weigh much less than steel and cast iron pipes, etc., so there is no need to spend a lot of money on transportation.

-

Because they can be welded and used with a coupler, their installation is very fast. It is possible to produce these pipes in different diameters (inner diameter) from 110 to 4000 mm, each of which has its own application.

-

A very important and causal feature of carogite is that it is not used by rodents and animals such as mice, etc. because it has no nutritional value at all.

What is the use of these pipes ?!

Carogit pipe has many applications according to the mentioned characteristics and is used in almost all industries that need piping to transfer different materials:

-

Rainwater collection and transmission systems

-

Collection and transfer of industrial, hospital, municipal, domestic and agricultural wastewater

-

Collect and transfer acidic, alkaline and salt substances

-

Agricultural systems for drainage and irrigation in agriculture

-

Industrial facilities for water treatment

-

Sewer pipes

-

Transfer of liquids and effluents from storage and treatment tanks

Note, however, that recent advances in the production of corrugated pipe have led to other applications being mentioned from time to time. Note that for each of the above applications, a specific type is used. For example, in drainage and agriculture, their walls have holes to collect both underground materials and in areas where waste is buried, the solution To collect sodium and be used in agriculture for irrigation and water transfer.

Types of corrugated pipes and applications of each

Carogit pipes have different applications based on their size, which is not bad to get acquainted with these cases (the mentioned numbers indicate the inner diameter in millimeters):

-

Carogitsize 110 pipe This type of pipe is not widely used because sometimes due to the sinusoidal flow of sewage, it will clog the pipe, especially if its solids are high. Its only mechanical resistance is 31.5 kN. It is usually used for sheaths around power cables and is most used in Turkmenistan.

-

Carogitsize Pipe 125 This type of pipe is mostly used to collect domestic sewage in alleys that are 8 meters long and, of course, only for 2-unit houses. Another use is to collect rainwater, part of which must be cut to sink the cleaning paddle when needed. Its only mechanical resistance is 31.5 kN.

-

Carogit pipe size 160 is the most widely used type of carogit pipes that are produced in various mechanical or annular resistances such as 8, 16, 31.5 and 64 kN and is used for 10 meter alleys to collect domestic sewage.

-

Carogit size 200 pipe is one of the most widely used and widely used sewage pipes that all factories have a very active production line that many customers want to buy. Applications include sewage, drainage and sheathing around the cable and protection of valves in drip irrigation.

-

After size 200, corrugated pipe is the most widely used type of sewage and drainage corrugated pipes, which is also called 10-inch corrugated pipe. Of course, note that sometimes they are also produced in the form of 300 mm, which is due to the standard deviation in the production line.

-

Carogitsize 315 pipe is one of the most widely used pipes among double-walled Carogit pipes, which is mostly used for sewage transfer in 20-meter streets and can be buried at a depth of 7 meters, but in a type with mechanical and annular resistance. 64 kN is produced. It is possible to bury the pipe at greater depths.

-

Carogitsize Pipe 400 This type of pipe is used to build manholes, garbage shooting, sheaths around thick telecommunication cables and power cables.

-

Carogit Size 500 Tube This type of pipe is widely used in urban ago, which can be produced in a spiral or carogit-spiral combination. Consumption of this type of pipes is very low.

-

Carogit pipe size 600 This type of pipe is produced with different mechanical resistances of 16, 31.5 and 64 kN, which depends on the type of pressure and depth that will be applied to them. These types of pipes are used to collect and transport sewage, produce manhole and even sewer pipes for septic tanks.

-

Carogitsize 700 pipes These types of pipes are not widely used not only in Iran but also in the world and are only custom made and its outer diameter depends on the depth of their installation and design. If used, it will only be used to collect sewage from 30-meter streets, industrial towns and factories.

-

800 to 3200 mm corrugated pipe Note that due to the subject under discussion, ie corrugated pipes, we refused to separate and use the 800 to 3200 size, because basically from 800 to 2500, it enters the spiral type and from 2500 onwards. It is a Core Tube type. But because the use of this type of tubes with the word carogit is common, they are called by the same name, which are actually spiral and cortical types, a special and advanced type of carogit, which we will point out at the end of the article.

Technical specifications and quality tests for the production of corrugated pipes

12 different quality tests are performed to confirm the quality of corrugated pipes, which are:

-

Density test of raw materials according to ISIRI175-5 standard and product according to ISIRI9116 standard

-

Melt flow index test according to ISIRI6980 and ISIRI9116 standards for raw materials and products, respectively

-

Long Term Ring Resistance Test according to ISIRI9110 standard, DIN1961

-

Short Term Ring Resistance Test according to ISIRI9116 and ISO9969 standards

-

Flexibility test according to ISIRI9116 and EN1446 standards

-

Soot test in corrugated pipes according to ISIRI7175-2 and ISIRI9116 standards

-

Testing the soot distribution of corrugated pipes according to ISIRI7175-6 and ISIRI9116 standards

-

Impact Resistance test according to ISIRI9116 and EN744 standards

-

Permitted thermal return test according to ISIRI9116 and ISIRI7175-3 standards

-

Linear tensile test of welding corrugated pipes according to ISIRI9116 and EN979 standards

-

Appearance testing according to ISIRI9116 standard

-

Spot marking according to ISIRI9116 standard

How to connect this type of pipe ?!

The fittings used for the corrugated pipe include two-piece and three-piece conversion elbows, tees and 45 and 90 degree elbows, three-way conversions, four-way, cap and bushing, etc. In some cases, they are produced from a mold and a piece, and in some cases, they use extrusion welding.

The reason why this type of fittings is used for corrugated pipes is that because they are polyethylene, they last as long as the pipes themselves, their appearance is exactly the same as corrugated pipes, ie the grooved outer, concave and inner surface is completely smooth. So uniformity is maintained throughout the structure, their installation does not require a professional and trained technician and they are also UV resistant.

What are the advantages of these pipes ?!

Carogit pipes have many advantages that you have certainly realized to a large extent by now, but to summarize what has been said so far, we will review and explain the advantages of Carogit pipes, which are as follows:

-

Extremely resistant to liquids with high acidity and alkalinity

-

High resistance to the sun’s UV rays

-

High resistance up to -70 degrees Celsius

-

Very high resistance at different soil depths due to production with very high mechanical or annular resistance up to 64 kN that can withstand depth pressures higher than 7 meters

-

Quick and easy installation and special connections, the installation of which does not require a professional and trained technician

-

Lower weight so that more of them can be moved in each trailer and transportation costs are not very high; Unlike steel and cast iron pipes and so on

-

High production speed

-

Production in different sizes with different applications

-

Smooth inner surface that prevents the deposition of passing materials and does not suffer from pressure drop and flow rate at long distances such as hundreds of kilometers of fluids and liquids

-

Exterior convex surface that relieves and does not eliminate peripheral and overhead pressures

-

Resistance to rodents because it has no nutritional value

-

Extremely durable and long lasting up to 100 years

Request product advice

The difference between a corrugated and a spiral pipe

295 / 5000

Translation results

Spiral corrugated pipes, although similar to corrugated pipes, are made of HDPE type polyethylene and spiral type can also be used to transfer fluids and sewage from domestic to industrial type, but their differences are not small and due to their importance. Frequently asked topics and questions from our customers:

- Carogit pipes are usually produced from 110 to 800 diameter or sometimes up to 1200 mm size corrugated pipes, but in the type of spiral pipes, their diameter varies from 800 to 3200 mm.

- In very large projects, it makes more sense to use spiral pipes

- The annular mechanical resistance or working pressure that corrugated pipes can withstand varies in the form of 8, 16, 31.5 and 64 kN, but in the spiral type it is 16 and 31.5.

- Carogit pipe fittings are mostly in the form of couplers or males and females, but in the spiral type they are in the form of extrusion welds in which the leakage is zero.

- In spiral pipes, their smooth and polished inner surface has more color variety

The difference between corrugated pipe and Cortiob tube

Carogit Cortiop tube is the newer generation of spiral tubes and is more advanced, so in this section we are going to compare it with corrugated tube:

- In Cortiop pipes, in addition to the use of extrusion welding, which reduces the possibility of leakage to zero, and in case of damage, the damaged part does not need to be replaced and can be removed by re-welding, different profiles can be used for the location Used to connect up to 1.5 times more specific resistance of this part.

- The external resistance of this type of pipe is almost similar to the spiral type of corrugated pipe and they bear the same external pressure, but the type of coating in them is such that they have a much higher resistance to the sun’s UV rays.

- These types of pipes are seamless or without welding line and therefore their stability and durability are much higher.

- Compliance with DVS2207-09 standard has made it possible to use industrial and domestic wastewater in all industries, and it is still possible to use extrusion welding, which is limited in the spiral type and is not compatible with this standard.

- Fully first-class machines made in Germany are the only machines used to make cortiopa tubes, so there is no substandard type on the market.

The cost of buying

Due to the price fluctuations that exist for polyethylene materials, a fixed price can not be considered and therefore you should contact sales experts to discuss the price at the time of purchase. Due to its wide and unique applications and benefits, corrugated pipe has attracted a lot of sales, and the factors that affect its price are:

- Rate of high density polyethylene (HDPE)

- Type and amount of raw materials consumed

- Place of production of the pipe

- Tube size and pressure tolerance, expressed in millimeters and kilowatts, respectively

- Length of corrugated pipe, which are produced in branches of 3, 6 and 12 meters

- Required area

Therefore, note that based on various invoices and parameters, the price also changes, which is the only way to contact the sales unit and specify the type of order and receive a free pre-invoice so that the final price can be explained to you in detail.

Note that receiving free advice and purchasing from reputable manufacturing companies plays a big role in the success of projects, especially since you have to pay a lot of money to buy them, so it is recommended that you buy with complete information in this regard. You can use the expert advice of Neshagostar Company by visiting the Contact Us page for free.